- English

- 简体中文

- Esperanto

- Afrikaans

- Català

- שפה עברית

- Cymraeg

- Galego

- 繁体中文

- Latviešu

- icelandic

- ייִדיש

- беларускі

- Hrvatski

- Kreyòl ayisyen

- Shqiptar

- Malti

- lugha ya Kiswahili

- አማርኛ

- Bosanski

- Frysk

- ភាសាខ្មែរ

- ქართული

- ગુજરાતી

- Hausa

- Кыргыз тили

- ಕನ್ನಡ

- Corsa

- Kurdî

- മലയാളം

- Maori

- Монгол хэл

- Hmong

- IsiXhosa

- Zulu

- Punjabi

- پښتو

- Chichewa

- Samoa

- Sesotho

- සිංහල

- Gàidhlig

- Cebuano

- Somali

- Тоҷикӣ

- O'zbek

- Hawaiian

- سنڌي

- Shinra

- Հայերեն

- Igbo

- Sundanese

- Lëtzebuergesch

- Malagasy

- Yoruba

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Dust Particles Pneumatic Conveying Equipment

Send Inquiry

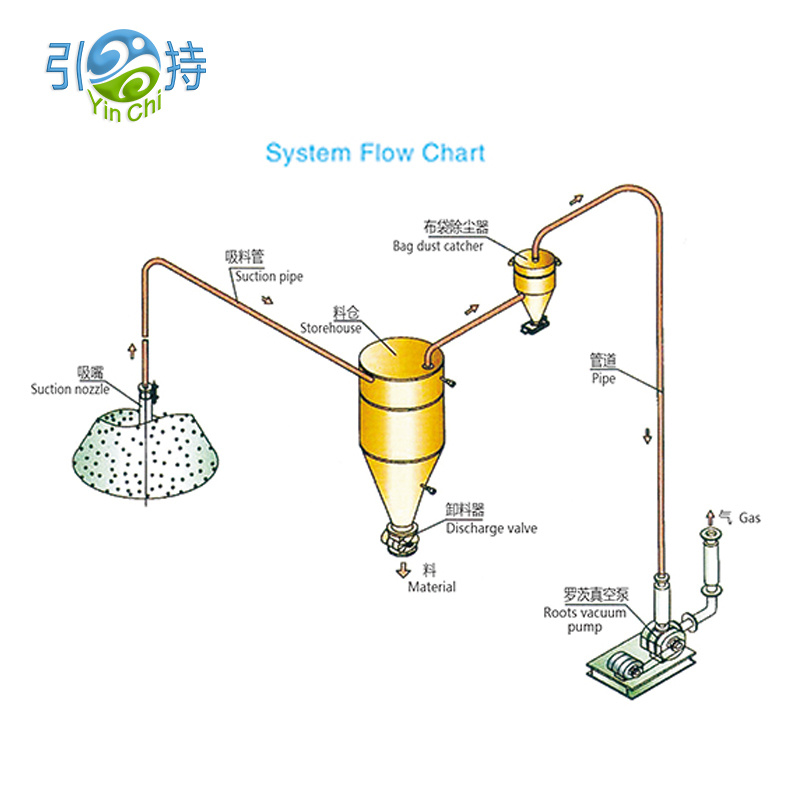

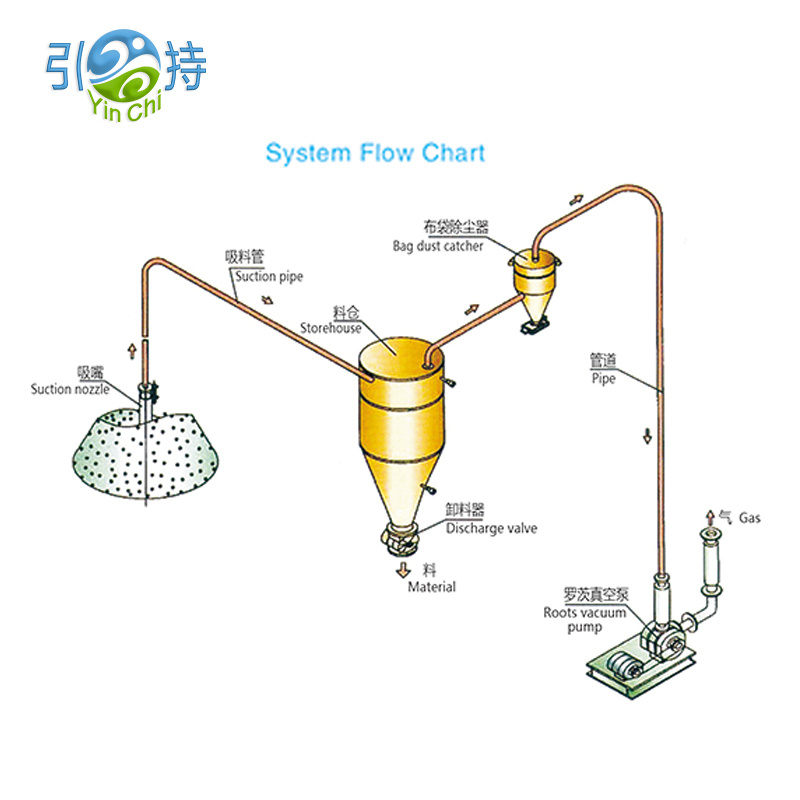

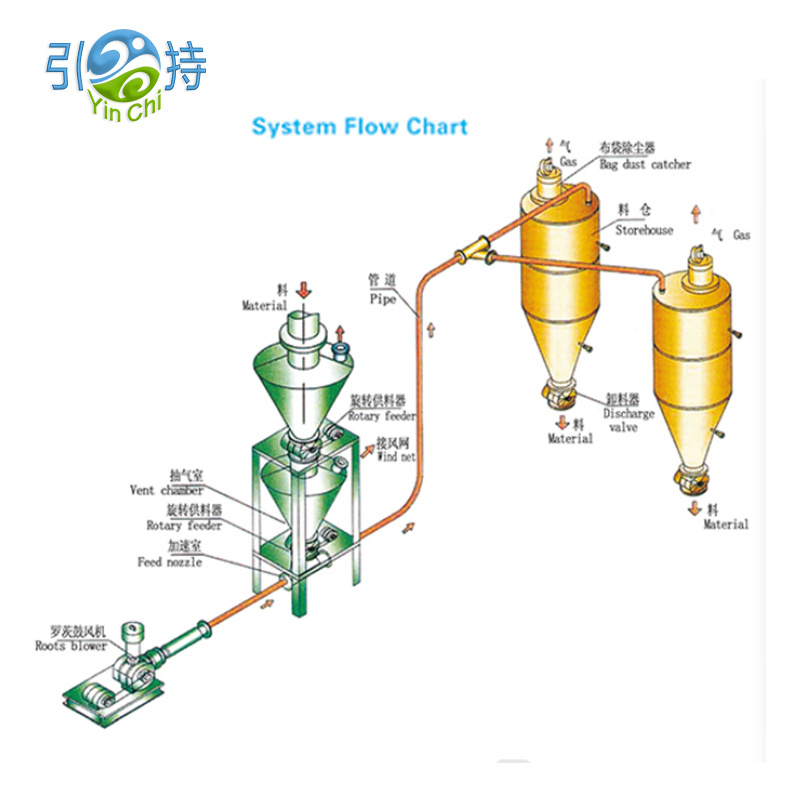

Pneumatic conveying means using air(or gas) as transportationpower and convey dispersed solid material in the pipe.

Powder Pneumatic Conveying Device Feature:

Variable arrangement of the pipe makes the production craft process more reasonable.

The sustem is sealed and lead to few flying dust, it benefit for envionment protection.

Few movement parts, convenient maintenance,automatic control can be realized easily.

High efficiency of transportation reduce the cost of packing,loading and unloading.

Make the matedal avoid being damped, polluted, damaged, and mixed with other material, the quality of conveying is assured.

Vadous operation process can be realized meanwile for the conveying,such as mixture, crush, grade, dryness cooling, and dust collection.

Send the material from couple place to one place and from one place to couple place, reatize far distance operation.

For the material with erratic chemical character, can adopt inertia gas conveying.

Dust Particles Pneumatic Conveying Equipment

The points availatle working-fault variety aggregates of perfomance each material conveying equipment for perfomance and efficiency has very big effect. Thereore in the selexted device before/the performance measurement. Suitable for conveying material as common:

|

Flour |

Bean cake |

Season powder |

Fishmeal |

Wheat |

Coca |

Salt |

Com |

Soybean |

Potato powder |

hull |

|

Dry leavening |

Cottonseed |

Fibrin |

Amylum |

Granule |

Fodder |

Tobacco leaf |

French chalk |

Dolomite |

Powdered glucose |

Monosodum glutamake |

|

Limestone |

Magnesia |

Aluminum dioxide |

Titanium whiteing |

kaolin |

Fluoresce powder |

Boric moist soil |

clay |

Laterite |

Lmenite powder |

Rice hull |

|

White dust |

Fedspar |

Scour pwder |

Fertilize |

Glauber's |

Carbamide |

Zinc oxide |

Calcium hydroxide |

Sodium carbonate |

Cement |

Gaphite |

|

silica gel |

Sodium nitrate |

Hydroxid aluminum |

Chlorate |

Phosphate |

Phosphatic |

Borax |

Land plaster |

Zinc powder |

Mine Powder |

Silicon aluminum ball |

|

Nickel powder |

Carbon blace |

Ferrice |

HDPE |

PTA |

PET |

ABS |

SBS |

PVA |

PVC |

EPS |

|

Coal powder |

Flyash |

Nylon slices |

Carbon element |

Coke pranule |

Cement |

Lron pellet |

Rubber granule |

Sawdust |

Biology enzyme |

PPS |

|

Accelerant |

Heavy calcium |

Land plaster |

Fiberglass |

Lusine |

Bran |

Found day |

Dry salt |

Protein |

MOCA |

CPE |

|

Germ |

Fruit dreg |

Soybean |

Gelatin |

Corundum |

Z silica gel |

Lime powder |

White stone powder |

BHT |

Soap grain |

Cobalt powder |

|

Sour cream |

Cotncob powder |

Thin film |

Com fibers |

PVC modifier |

Alkaline cellulose |

Magnesium |

Alumina |

Lxalic acid cobalt powder |

Aluminum particles |

PS |

|

PP |

Petrolem coke |

Slag powder |

PE |

Electrially calcined coal |

Smelter Coke |

|

|

|

|

|

Shandong Yinte Environmental Protection Equipment Co., Ltd. is located in Zhangqiu, Jinan, Shandong, with a registered capital of 10 million yuan. It is committed to providing complete pneumatic conveying system solutions for various large, medium, and small enterprises.

Our company has a professional technical design and development team as well as an equipment production team, mainly producing pneumatic conveying related equipment such as rotary feeders, Roots blowers, and bag filters.

In the process of rapid growth, our company adheres to the corporate philosophy of dedication, integrity, harmony, and innovation, insisting on only producing sticky products, not manufacturing defective products, and not releasing defective products. We are committed to facing the pain points of the industry, adhering to our own product characteristics, constantly innovating and optimizing our products. Through our excellent design, production, and service, we have solved the problems of desulfurization, denitrification, dust removal, and ash removal in pneumatic conveying for many companies, and have received unanimous praise from both new and old customers!