- English

- 简体中文

- Esperanto

- Afrikaans

- Català

- שפה עברית

- Cymraeg

- Galego

- 繁体中文

- Latviešu

- icelandic

- ייִדיש

- беларускі

- Hrvatski

- Kreyòl ayisyen

- Shqiptar

- Malti

- lugha ya Kiswahili

- አማርኛ

- Bosanski

- Frysk

- ភាសាខ្មែរ

- ქართული

- ગુજરાતી

- Hausa

- Кыргыз тили

- ಕನ್ನಡ

- Corsa

- Kurdî

- മലയാളം

- Maori

- Монгол хэл

- Hmong

- IsiXhosa

- Zulu

- Punjabi

- پښتو

- Chichewa

- Samoa

- Sesotho

- සිංහල

- Gàidhlig

- Cebuano

- Somali

- Тоҷикӣ

- O'zbek

- Hawaiian

- سنڌي

- Shinra

- Հայերեն

- Igbo

- Sundanese

- Lëtzebuergesch

- Malagasy

- Yoruba

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Pneumatic conveying system

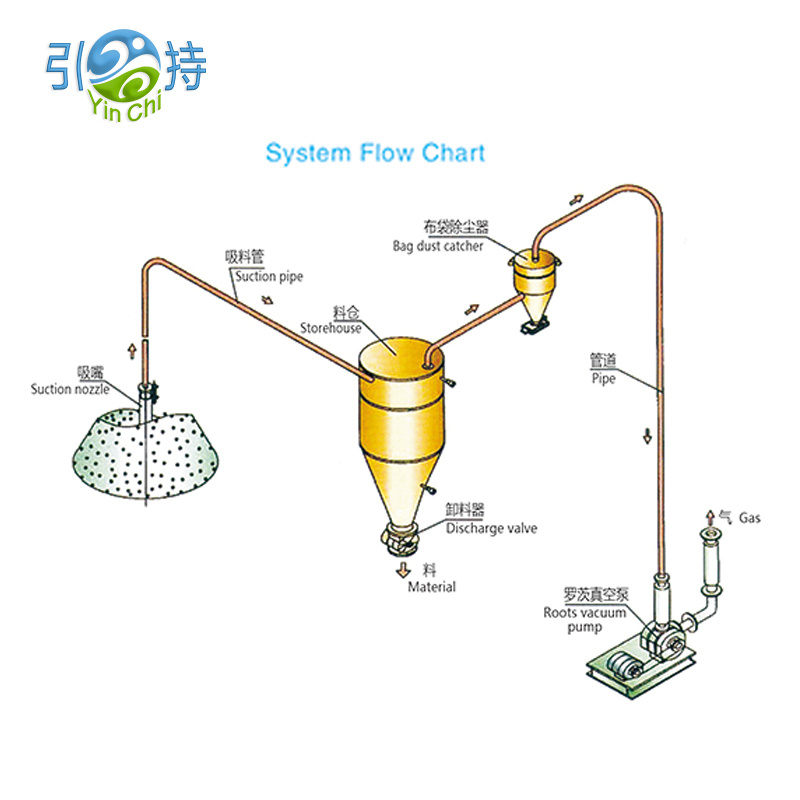

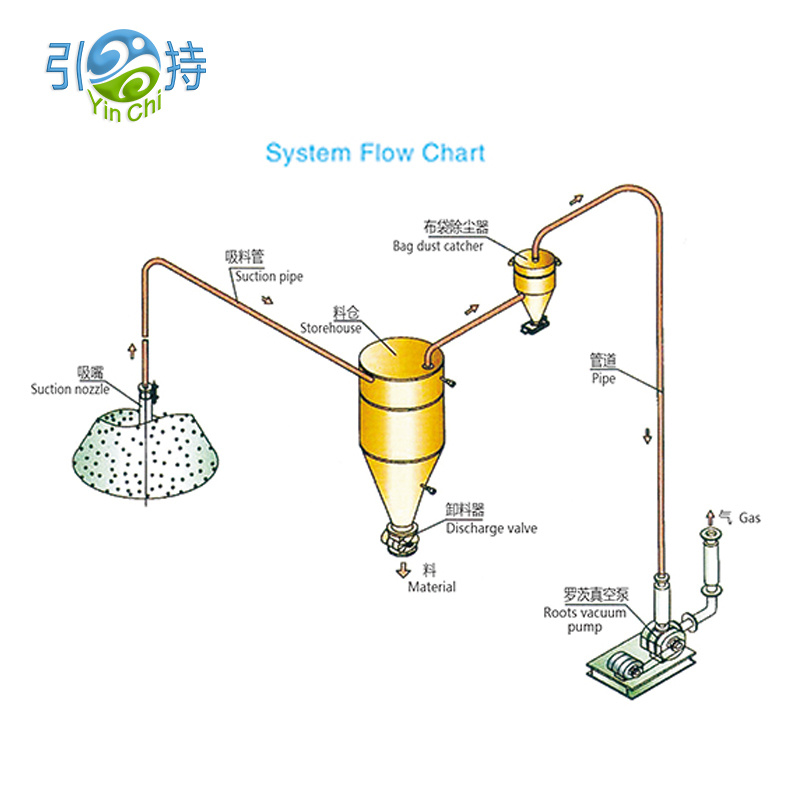

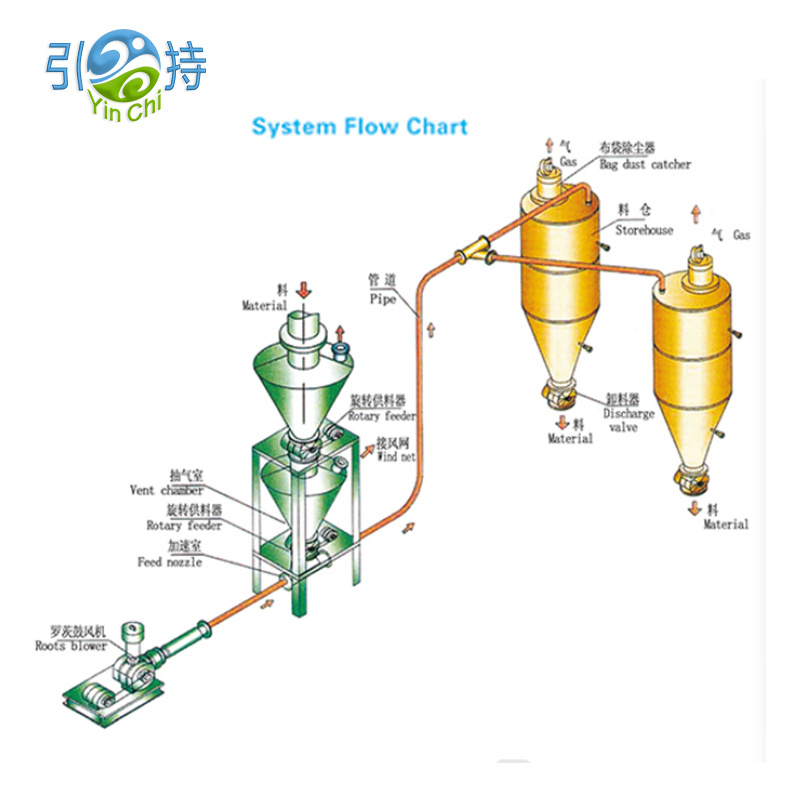

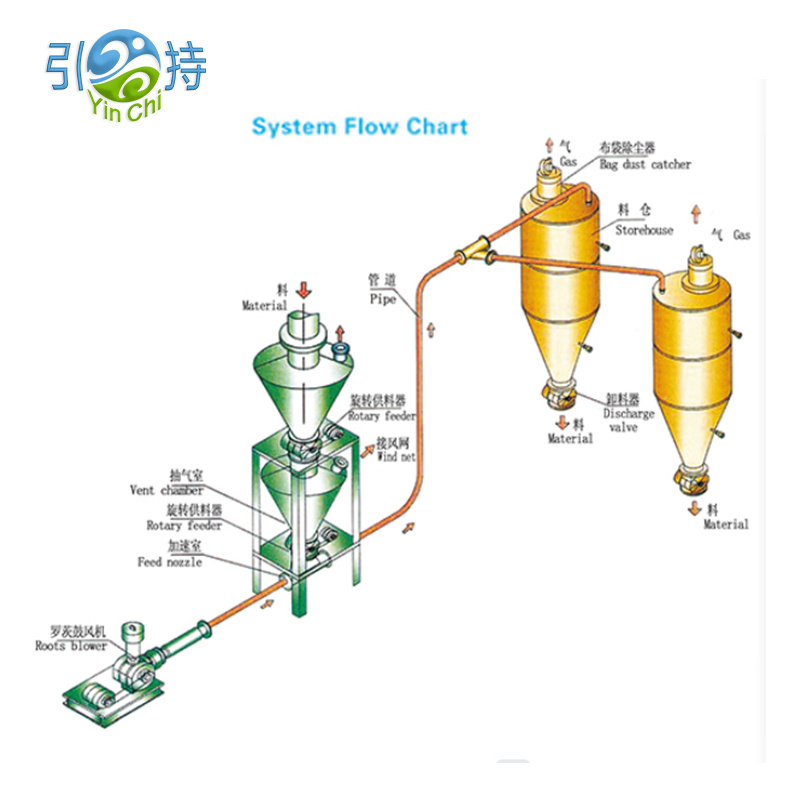

The working principle of pneumatic conveying system mainly involves the interaction between airflow and materials.

Specifically, the pneumatic conveying system transports materials from the starting point to the endpoint through high-pressure air or compressed air, which can be horizontal, vertical, or inclined. During the transportation process, the material is driven by the airflow and suspended in the pipeline, or forms a group to move along the pipeline. Pneumatic conveying systems can be divided into positive pressure conveying and negative pressure conveying, as well as dilute phase conveying and dense phase conveying. Positive pressure conveying uses high-pressure air to push the material, while negative pressure conveying uses vacuum suction to suck the material into the collection point. Dilute phase conveying is usually used for situations where the conveying distance is short and the material content is low, while dense phase conveying is suitable for long-distance and high concentration material conveying.

In addition, pneumatic conveying systems can also perform physical operations such as heating, cooling, drying, and airflow classification of materials simultaneously during the conveying process, or perform certain chemical operations.

- View as

Positive Pressure Dilute Phase Pneumatic Conveying

Yinchi's Positive Pressure Dilute Phase Pneumatic Conveying system deliver gentle, high-speed transport for powders and granules across industries like food, pharma, and chemicals. Ideal for non-abrasive materials requiring fast, long-distance transfer. Custom configurations available.

Read MoreSend InquiryCone Bottom Tanks

The Yinchi Cone Bottom Tanks by Shandong Yinchi is engineered for efficient bulk material handling across industries like agriculture and construction. Featuring advanced pneumatic conveying technology, it ensures reliable performance and minimal maintenance.

Read MoreSend InquiryLow-Maintenance Pneumatic Conveying System

Low-Maintenance Pneumatic Conveying System has the ability to centrally transport cement from multiple locations to one location; The characteristics of low conveying pressure, reliable conveying, and simple equipment. The transported material will not escape from the system; It can prevent dust from flying at the material collection point, resulting in high production efficiency.

Read MoreSend InquiryCustomizable Rotary Valve Rotary Feeders

Our Customizable Rotary Valve Rotary Feeders is designed to efficiently and accurately transport various particles and powder materials. Using durable materials and advanced technology to ensure stable operation and long lifespan.

Read MoreSend InquiryAutomatic Feeding Pneumatic Conveying Machine System

Automatic Feeding Pneumatic Conveying Machine System has the ability to centrally transport cement from multiple locations to one location; The characteristics of low conveying pressure, reliable conveying, and simple equipment. The transported material will not escape from the system; It can prevent dust from flying at the material collection point, resulting in high production efficiency.

Read MoreSend InquiryDust Particles Pneumatic Conveying Equipment

Dust Particles Pneumatic Conveying Equipment has the ability to centrally transport cement from multiple locations to one location; The characteristics of low conveying pressure, reliable conveying, and simple equipment. The transported material will not escape from the system; It can prevent dust from flying at the material collection point, resulting in high production efficiency.

Read MoreSend InquiryQuicklime Pneumatic Conveying System

Quicklime Pneumatic Conveying System has the ability to centrally transport cement from multiple locations to one location; The characteristics of low conveying pressure, reliable conveying, and simple equipment. The transported material will not escape from the system; It can prevent dust from flying at the material collection point, resulting in high production efficiency.

Read MoreSend InquiryWheat Flour Grain Pneumatic Conveyor

Shandong Yinchi's Wheat Flour Grain Pneumatic Conveyor assists in efficient industrial production.

Read MoreSend Inquiry